STEEL

Carbon, Alloy and Bearing Steel for

Various Industries Application.

Doosan Pipes is an established market leader in the production of carbon steel seamless pipes. We produce carbon steel pipes like API 5L GR B/X42/X52/X60/X65/X70/X80/X100 in PSL1 & PSL2 categories with a special emphasis on high quality and requirements of oil & gas sector. With over 15 years of experience in the manufacture of special steels our strength lies in our ability to produce very clean steels consistently and cost effectively, to develop and custom produce steels that meet specific mechanical or metallurgical requirements; and to deliver small lots of steels.

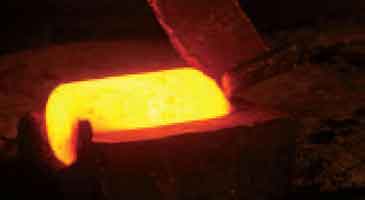

MODERN EQUIPMENT AND METHODS

We operate one of the most modern steel plants in the country. All our steel is produced through the electric arc furnace (EAF) route, is ladle refined, vacuum degassed, continuous cast and rolled. These primary equipments are supplemented by best in class quality enhancing devices with the singular objective of producing the best steel.

CAREFULLY CHOSEN INPUTS

The quality of inputs used for melting has a direct bearing on the quality of the output. For this reason, we use a very carefully chosen mix of raw material. We have a trusted set of suppliers all of whom are periodically audited to ensure adherence to our standards. In addition, we test all incoming material for radiation and other hazardous contaminants.

CLEAN STEEL PROCESS

Doosan Pipes prides itself on manufacturing the cleanest steel in the country, on par with the best worldwide this is entirely attributable to our steel making practices. While good equipment is a prerequisite for making Clean Steel, at Doosan Pipes, we believe that good practices are even more vital. While modern equipment may be procured at a cost, good practices are much more difficult to develop, and institutionalize it takes determination, time and painstaking effort. For this reason, throughout our 5 years of steel making history, we have focused on developing process knowhow, training people, and creating a committed quality culture. We are proud to say that our processes and practices are second to none.

APPLICATION BASED STEEL MAKING

At Doosan Pipes, we like to understand where our steel is used. Where possible, our Technology Process Group (TPG) interacts with customers at the shop floor and at the R&D level to translate the customer’s product requirement into a steel specification and a steel making process specification. This “Application Based” approach enables to deliver the most suitable and cost effective product. Today, given our history and our approach, we have developed an understanding of hundreds of applications that use our steels and we can use that experience to help you either select a steel or to develop a new grade appropriate to your requirement.

|OPRODUCTION INFORMATION

| Installed Capacity | 350,00 MT/annum |

| Process Route | EAF – LRF – VD – CCM – RM |

| Heat size | 45MT |

| Products | 1) API 5L GR B – X100 PSL1/PSL2 Pipes.

2) ASTM Low Temp A333 GR 6 Pipes. 3) ASTM A106 GR B PIPES |

| Prodcution Range | Diameter: 1/2” NPS to 36” NPS, Thickness: 5MM to 80MM |